|

April 28th Meeting

"Hollow Forms Using Homemade Tools"

|

|

|

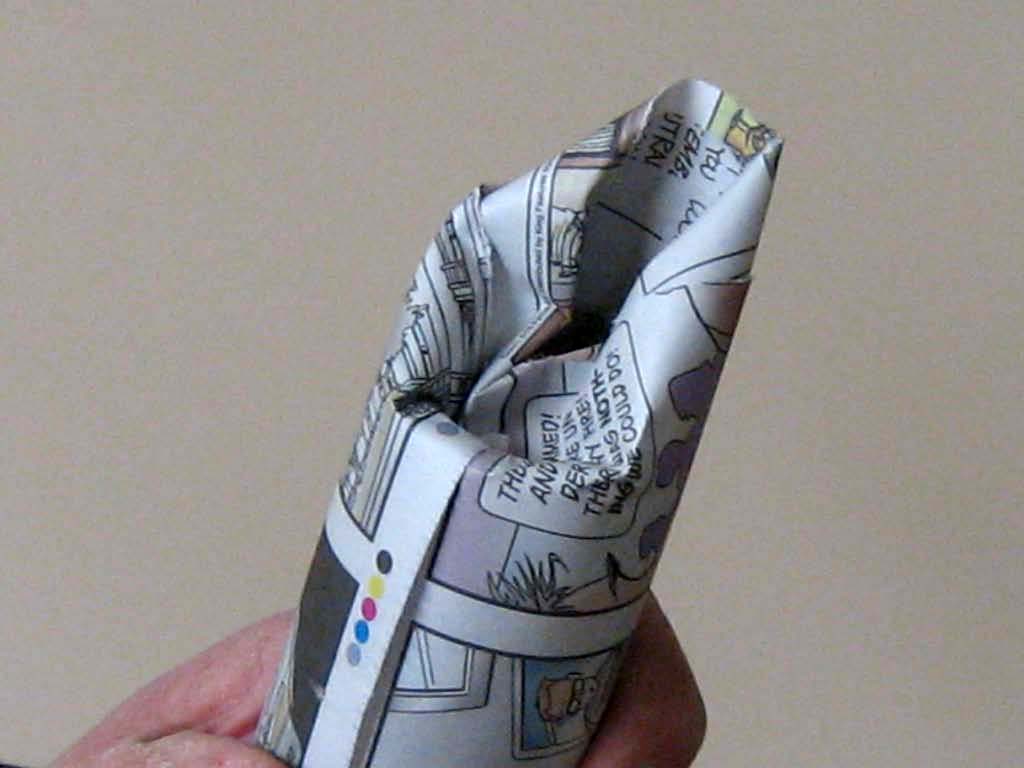

Dana Duffield,

the father of teenage triplets, showed us how frugal he had to get to feed his family and his turning hobby. Dana presented the details, complete with handouts, on

how to construct a deep hollowing system with laser guidance from common hardware store parts plus one carbide cutter from a

turning catalog. He then demonstrated the hollowing process. Along the way he showed us some clever aids he made, including a narrow tubular

attachment to his shop vacuum to suck chips out of the narrow opening of his hollow form.

Daring members to give it a try, he had several takers. Because of his expert instruction,

none of the members that took the challenge had blowups, and all felt they had a real learning experience.

|

|

Click here for Show and Tell Items from the April 28th meeting.

|

|

|

May 26th Meeting

"Three Methods of Threading"

Duane Hill Presents

Duane was instrumental in the founding of the Coulee Region Woodturners (CRW),

and served as their president for several years.

He is an accomplished woodturner and decorator of wood turnings. His presentation to ZVW was a preview of what he will demonstrate

at the 25th annual AAW symposium in Saint Paul, Minnesota, Friday June 24 through Sunday June 26, 2011.

Here is a synopsis of the three methods:

|

|

|

Cranking by hand, the Baxter jig moves the blank into a rotating cutting tool mounted in the headstock, allowing more flexibility in lathe speed and wood density

than the other two methods.

|

|

|

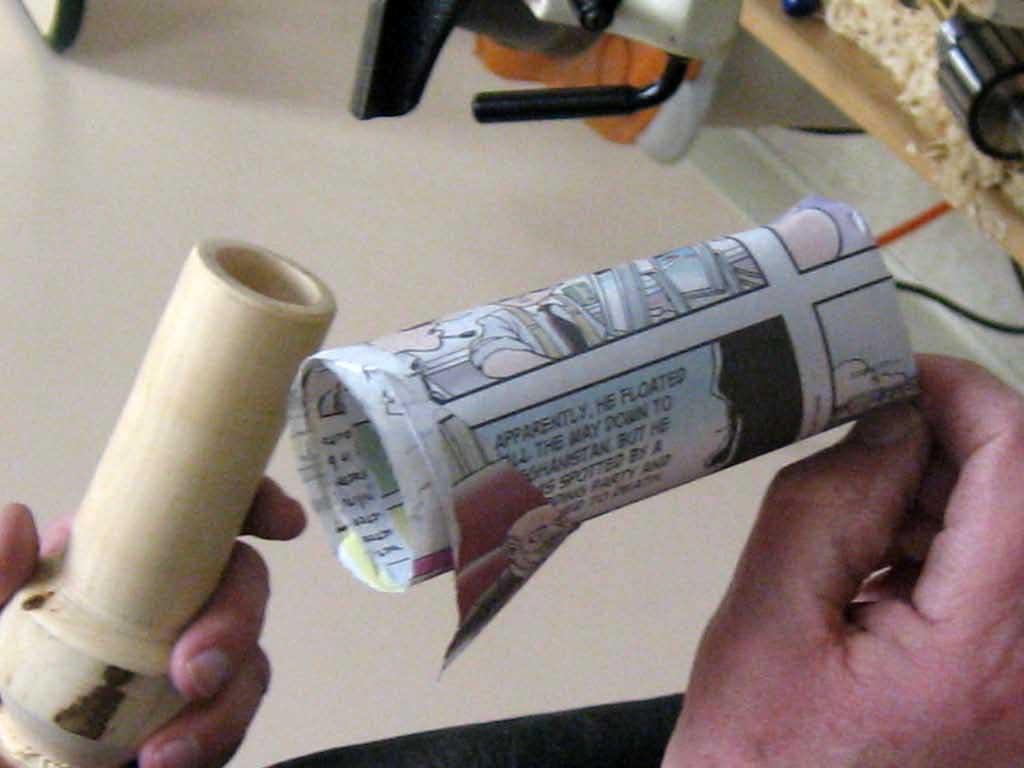

With a drilled blank in the headstock, and a tap held stationary, the lathe is used as a horizontal drill press.

The headstock spindle is turned by hand while the tailstock is advanced by hand, requiring a

coordinated pair of hands.

|

|

|

Thread chasing requires a slow lathe speed (200 rpm), very dense wood (such as boxwood), and rhythm, rhythm, rhythm.

|

|

|

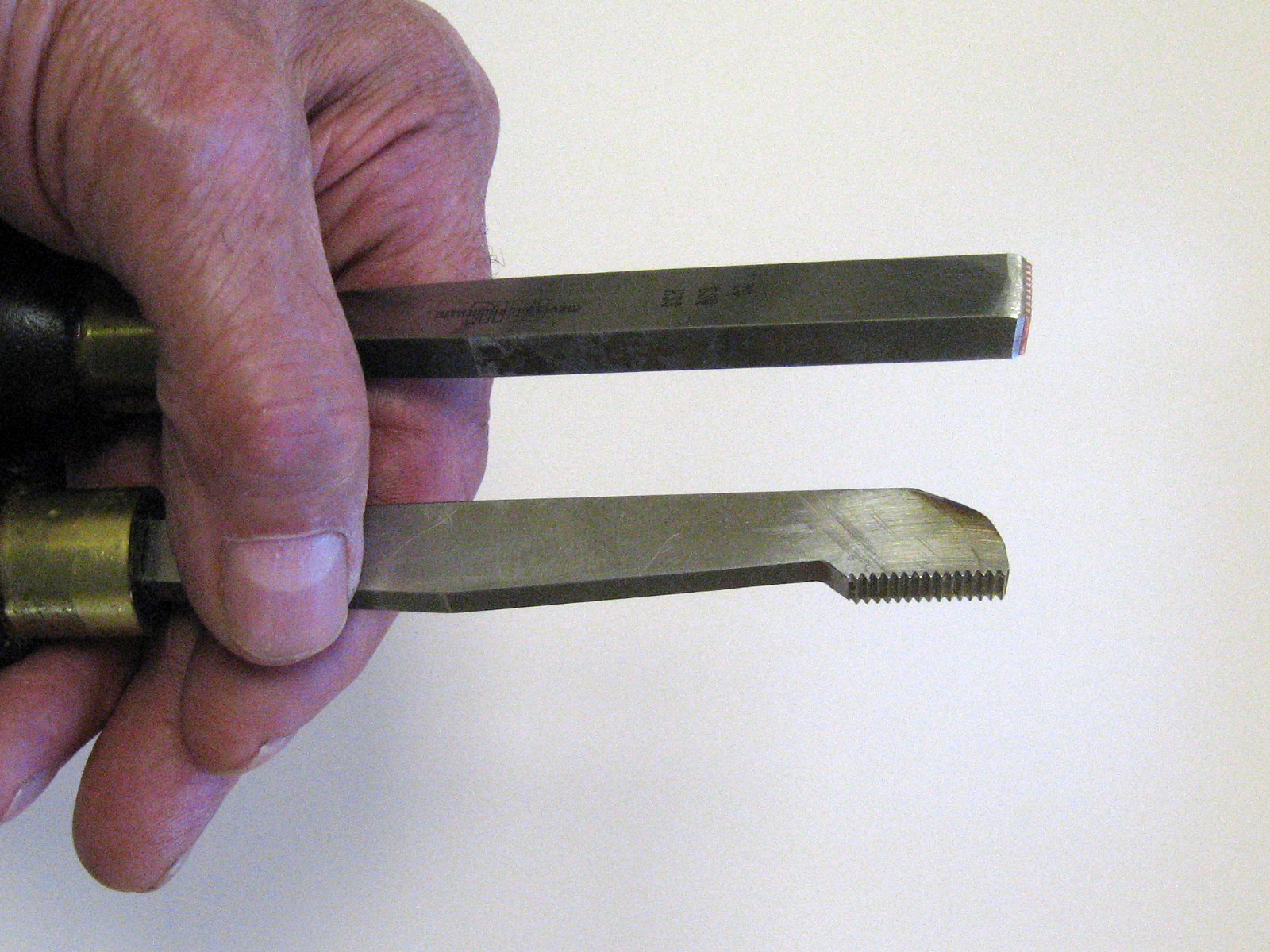

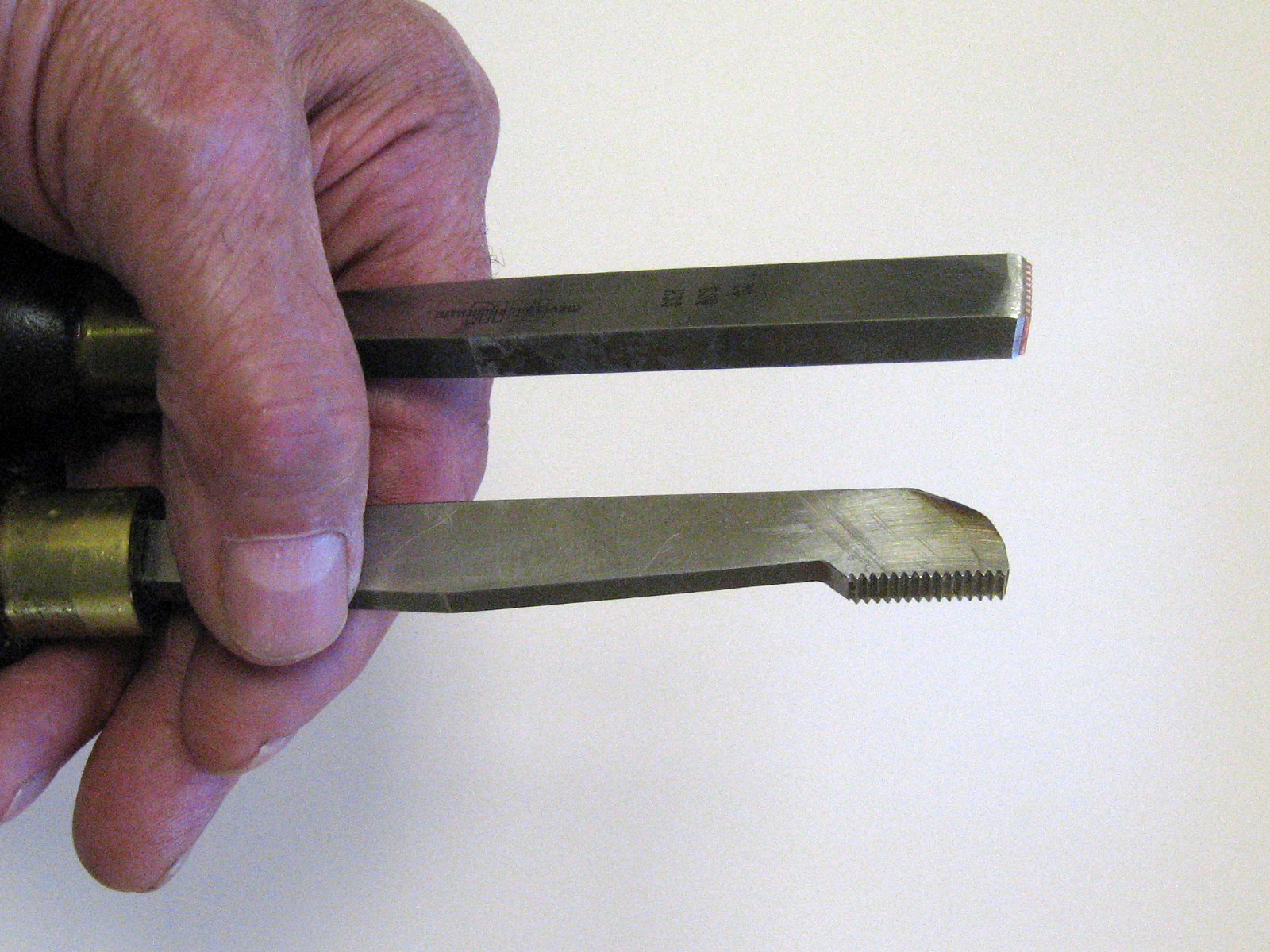

Chasing tools come in a matched pair, one tool for external threads (upper), and one tool for internal threads (lower).

|

|

Click here for Show and Tell Items from the May 26th meeting.

|

|

|

June 30th Meeting

"Off-Center Turning Jig"

|

|

|

Dave Dunn Presents

Apparently Dave found just what he was looking for at the AAW symposium trade show less than a week ago: a

small, adjustable off-center, indexing "face plate" to enable him to turn designs in his medallions.

|

|

|

Dave has just started to explore its possibilities, so he will probably bring some exotic eccentric creations to Show and Tell at future meetings,

but right now we will have to settle on medallion designs.

|

Below is a finished medallion turned in corian. The incised design is accented in black.

|

|

|

Click here for Show and Tell Items from the June 30th meeting.

|

|

|

July 28th Meeting

"Segmented Turnings"

|

|

|

Sheldon Bailey Presents

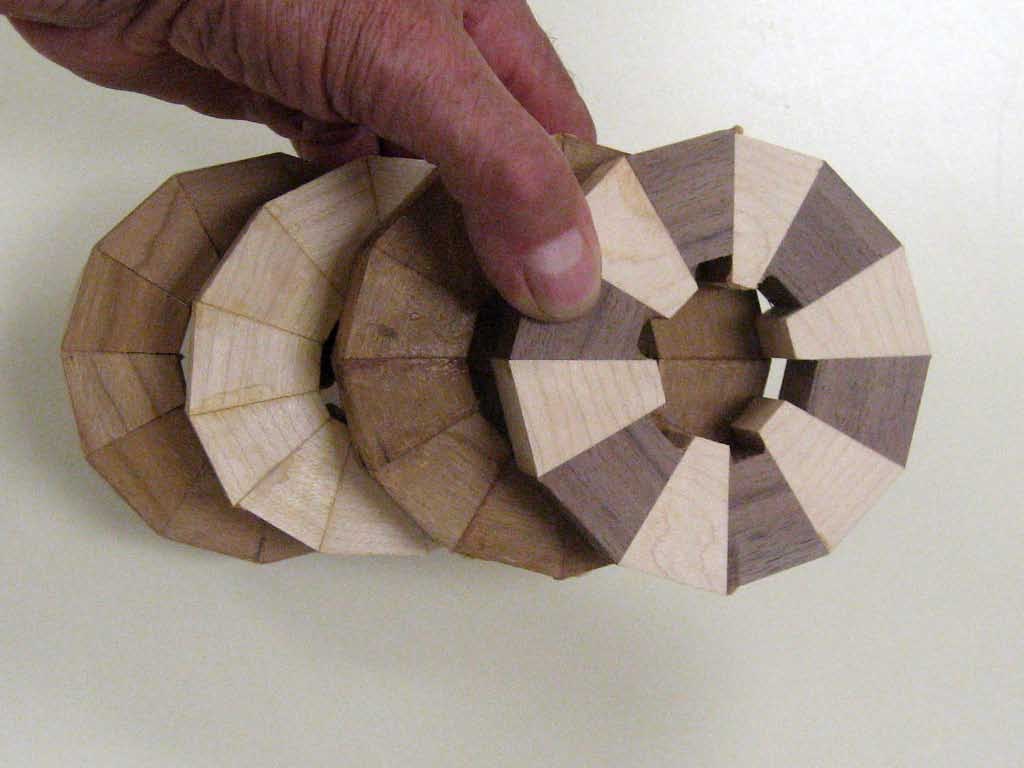

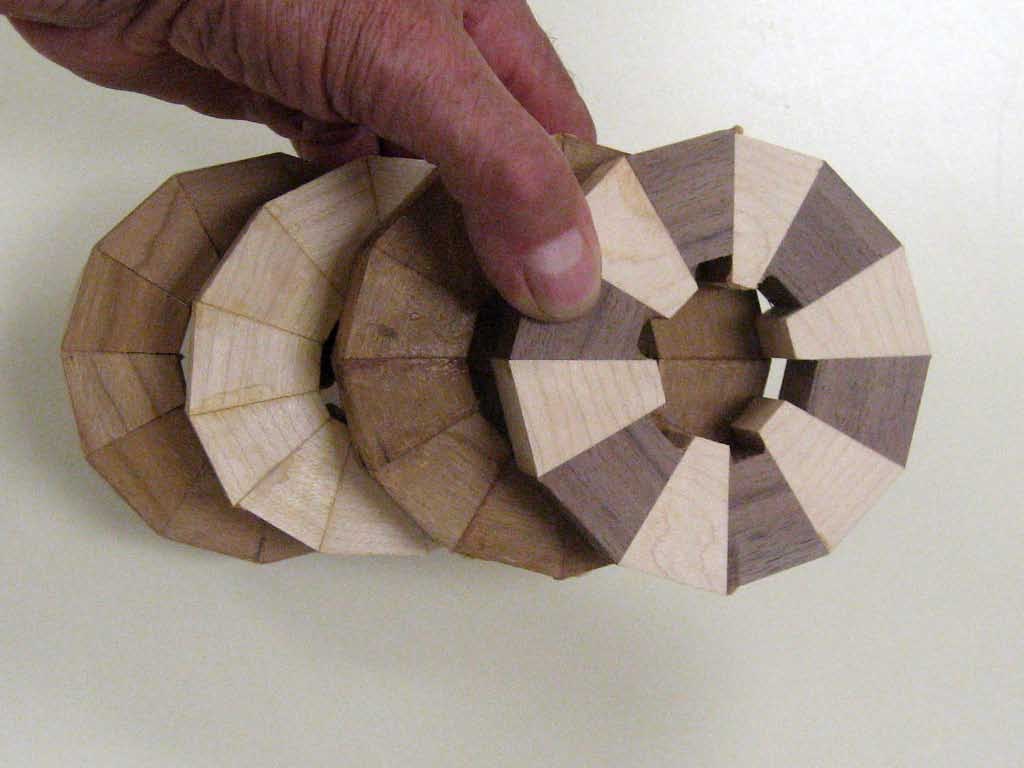

Sheldon chose a travel mug with a stainless steel liner as a project to show how he goes about creating a segmented turning.

|

|

|

Using a table (he handed out copies) showing dimensions

of segments based on the number of segments per disc and the desired ring diameter, he focused on the details of building a segmented turning blank.

|

Critical steps in making a flat, circular disk with uniform segments and no spaces between the segments

included sawing strips into segments in a way that cancelled out any saw misalignment. Showing us alternate methods of glue-up and

clamping gave us some flexibility in using what might be available.

|

Discs must be perfectly flat before they are glued up into a blank. Sheldon provided us with many tips on how to go through this process

for high quality results.

The turning portion of his demo concentrated on fitting the blank to the mug liner while leaving room for liner expansion for hot beverages.

|

|

Click here for Show and Tell Items from the July 28th meeting.

|

|

August 25th Meeting

"Vacuum Chucking"

|

|

Presented by

Bill Beckman

and

Duff Bement

If you wanted to know how to put together a vacuum chuck system on the cheap, this was the place to be.

Both Bill and Duff had scrounged for used or low cost vacuum pumps, purchased stock plumbing and air fittings at local stores,

and with much ingenuity produced low cost, but very functional vacuum chucking systems. They answered many questions from club members,

and gave many tips on how to fix turning blanks in their various chuck fixtures made from ABS sewer pipe caps and other low cost items.

|

|

|

|

|

Click here for Show and Tell Items from the August 25th meeting.

|

|

|

September 29th Meeting

"Annual Family Picnic"

|

|

This year's picnic was well attended. It was held in the New Haven Town Hall. Wayne VanEvery got the club-provided food, drinks, plates, etc.

together. Bill Beckman, as usual, made the coffee. Members contributed a wide variety of foods to make this pot luck meal very special.

After the meal and Show and Tell, attendees selected the 2011 Challenge Champion. Each year, at the August

meeting, wood is provided to those interested in entering a woodturning challenge. Each participating member then turns something, brings it to the picnic meeting,

and hopes that the attendees will vote for it. The winner gets to take home the coveted Bill Beckman corny Challenge Champion trophy and badge for one year.

Bill is our corn agronomist.

|

|

|

Click here for close-ups of individual challenge items.

|

|

|

This year's winner was Bob Post's walnut bowl. When it was suggested that Bob clear off his mantle to display the trophy,

he commented: "If I have to do that, next year I am not going to enter anything."

|

|

One of the Show and Tell items was Benny the Burrow shown below. Benny is being ridden by Addy. This demonstrates two things:

1. This was, indeed, a family picnic, and

2. Woodturning, combined with woodcarving, and flatwork can make for some pretty fun stuff.

|

|

|

Click here for Show and Tell items from the September 29th meeting.

|

|

|

October 27th Meeting

"Small Christmas Ornaments"

|

|

|

Lyle Solem Presents

Lyle first lectured on the very basics in making small Christmas ornaments. He then proceeded to turn a small snowman icicle, followed by another tear-dropped shaped ornament.

He uses water-based colored pens for the hat, scarf, and face, and follows this with a lacquer-based clear finish which does not cause the water-based colors to run.

|

|

|

Click here for Show and Tell items from the October 27th meeting.

|

|

|

November 17th Meeting

"Decorating: Marbling"

|

|

|

Lyle Solem Presents

Marbling can add another dimension to turned objects. It takes a bit of relatively inexpensive stuff that can

be obtained locally from a hobby shop and a grocery store. The procedure involves turning an object, such as a top, dipping it into an alum sizing, letting it dry, and

then dipping and gently rotating it into a film of paint floating on water. The paint film is created by dripping different colored paints onto a shallow

container of distilled water,

and then swirling and combing the surface with various objects to create a pattern that is then transferred to the object.

Lyle demonstrated creating the paint film. He then provided members with prepared discs to learn the transfer technique. Some of the results are shown below.

|

|

|

Click here to see a 16-minute video of this technique presented by The American Woodworker Magazine.

|

|

Click here for Show and Tell items from the November 17th meeting.

|

November 17th Election of ZVW Board Members

|

|

ZVW Board Members are elected for a 2-year term, with approximately half elected on an even year, and half on an odd year.

On November 17, 2011, Bill Beckman, Dennis Holt, Gar Pronk, and Todd VanDeWalker were elected to serve in 2012 and 2013.

At the next board meeting, club officers will be chosen by the board from all of the board members.

|

|

|

December 15th

"Holiday Social"

|

|

|

Excellent turnout of members and guest made this first holiday social a great success.

A raffle of donated turnings raised some money toward the club's goals of enhancing our inventory of demonstration equipment.

|

|

|

A wide selection of Show and Tell items provided our guests with a good idea of what we do.

|

|

|

|

|

|

|

|